Hot Working Steel

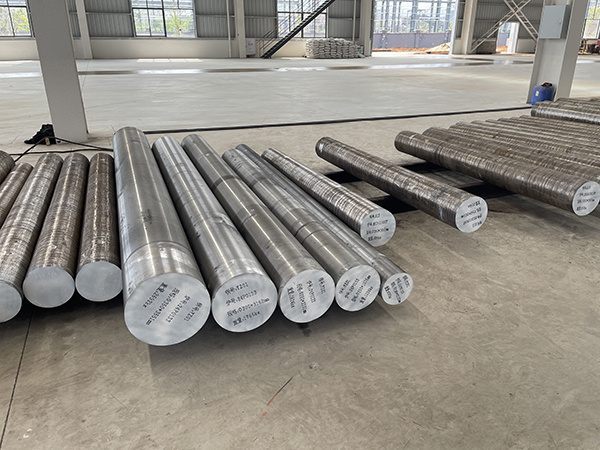

The main products are the H13 series, which can obtain high-purity raw material steel ingots through the steelmaking process of electric arc furnace EBT+external refining LF+vacuum VD+electroslag remelting ESR. The P can be controlled within ≤ 0.015% or even ≤ 0.012%, and the Mo/V content can be adjusted according to customer needs, providing personalized production services. The heat treatment process of multiple upsetting and drawing, high-temperature diffusion homogenization forging, and high-temperature solid solution ultra-fine treatment can effectively improve metallurgical defects such as carbide segregation, obtain a spheroidized structure with small and uniformly dispersed carbide particles, greatly improve the performance of the material, and greatly extend the life of the mold. The following are several product qualities of our company:

|

Steel grade |

Testing level | Metallographic structure | Lateral impact energy without notches | Hardness |

|

H11/1.2343 |

SEP1921 E/e |

AS9More Than |

≥250J |

HB≤200 |

|

H13/1.2344 |

SEP1921 E/e |

AS9More Than |

≥280J |

HB≤200 |

|

8407 |

SEP1921 E/e |

AS7More Than |

≥300J |

HB≤200 |

|

H18 |

SEP1921 E/e |

AS7More Than |

≥330J |

HB≤200 |

|

8418 |

SEP1921 E/e |

AS7More Than |

≥350J |

HB≤200 |

Product Cases Produced Recently

1.2343 (Mo1.12/V0.4)

Product specifications: 760 × 255 × L

Lateral impact energy result: 7 × 10 × 55

Impact energy without notches: 320J, 303J, 321J;

Metallographic structure:

H13 (Mo1.21/V0.82)

Product specifications: Φ 350 × L

Lateral impact energy result:7 x 10 x 55

Impact energy without notches: 302J, 296J, 294J;

Metallographic structure:

8407 (Mo1.41/V0.98)

Product specifications: Φ 450 × L

Lateral impact energy result:7 × 10 × 55

Impact energy without notch: 312J, 310J, 322J;

Metallographic structure:

YZ01 Performance Data

The production of steel ingots this time is 3.5tx3 pieces, with a total of 5 forged smooth round bars, with a production specification of ¥ 180- ¥ 350mm. Metallographic samples were taken from the middle 350 round bars, and the metallographic structure was rated as AS2. The performance data are as follows:

|

Number |

Steel grade |

Ingot shape |

Finished product specifications |

Sampling location |

Impact energy J |

|

1 |

YZ01 |

3.5T |

Φ250 |

End face center |

243、281、229 |

|

2 |

Φ280 |

|

|

||

|

3 |

3.5T |

Φ180 |

Steel ingot center |

196、225、211 |

|

|

4 |

Φ300 |

|

|

||

|

5 |

3.5T |

Φ350 |

End face center |

192、189、184 |

The impact specimen is quenched at 1030 ℃, tempered at 580 ℃ -600 ℃, and has a hardness of 44.6HRC. The average impact energy is above 180J, while the average impact energy of ordinary H13 in Huangshi area is generally below 200J (dissecting group 1 of ordinary H13 in Huangshi area, with a round rod specification of Φ 240, impact energy of 116J, 136J, 123J, and an average value of 125J). Compared to other types of H13, YZ01 mold steel has higher performance and more stable quality, and can be used as a substitute for ordinary H13.

Advantages of Press Production

H13 round bars in the Huangshi area are generally produced by direct elongation using a forging hammer, or by upsetting and elongation using a forging hammer. However, the forging hammer converts potential energy into kinetic energy and relies on impact force for deformation. Due to limited force, the upsetting effect is not good. The shape of the upsetted billet is similar to a dumbbell, and the two ends of the steel ingot are deformed by hammering, but the force cannot be transmitted to the middle part. Therefore, the crushing effect of the forging hammer is better on small round bars with a specification of ≤ 250. Round bars with a forging hammer production specification greater than diameter 250 generally have relatively thorough deformation at both ends, while insufficient deformation in the middle part, ultimately resulting in strong directionality of the product. This is reflected in severe strip segregation, qualified longitudinal impact energy, and low transverse impact energy (generally below 200J).

The press machine continuously applies static pressure, which has a more thorough effect on the crushing of the cast structure and the compaction of the center. The force is transmitted to the center, and the steel ingot becomes bulging after upsetting. Through multiple upsetting and drawing by the press machine, the material's performance can be improved and the isotropic performance can be better. This not only improves the overall performance, but also reduces the degree of segregation of the material, and the transverse impact energy and longitudinal impact energy are basically the same.

Contact Information

Address: No.1, Lingcheng Road, Lingcheng Industrial Park, Lingxiang Town, Dazhi City, Huangshi City, Hubei Province

Quick Navigation

Message consultation