Plastic mould steel

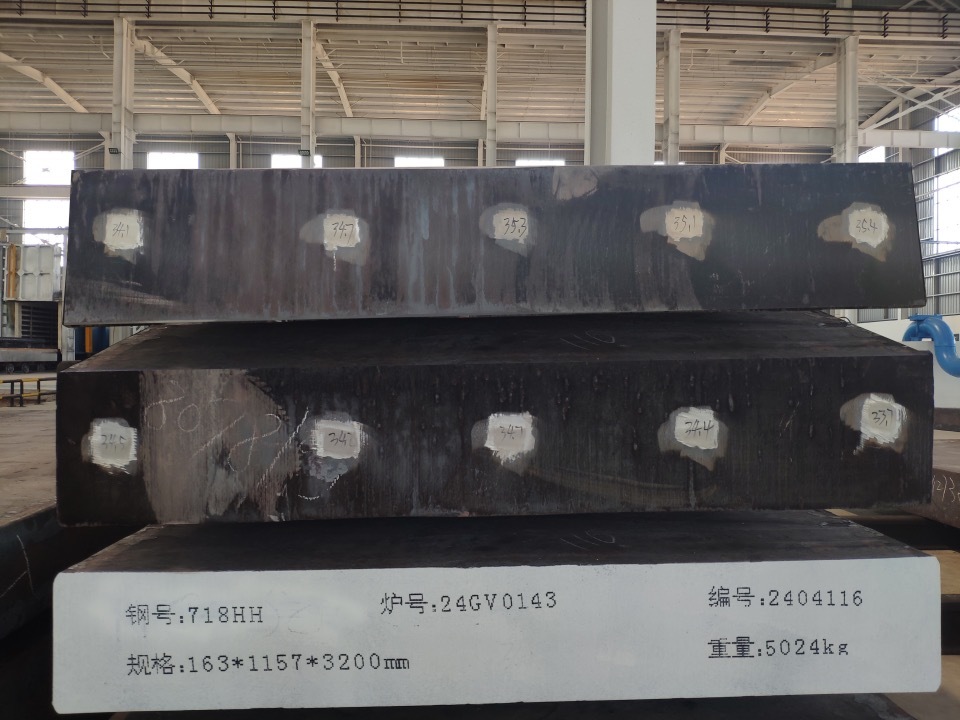

1.2311/P20, 718/1.2738, 1.2714 and other plastic mold steel is also one of our company's characteristic products, which can produce large-size round bars and modules. After pre-hardening treatment, the hardness is highly uniform, and the hardness deviation of the watch core is within 4HRC, which is very popular with customers. The Cr13 series plastic mold steel produced by our company has the characteristics of small carbide particles, uniform dispersion distribution, corrosion resistance, stainless steel, good mirror polishing, etc., and has a wide range of applications.

The important factors of mold materials are thermal strength and thermal stability. Common mold materials include working temperature, forming materials, and mold materials

<300 ℃ Zinc alloys Cr12, Cr12MoV, S-136, SLD, NAK80, GCr15, T8, T10.

300-500 ℃ aluminum alloy, copper alloy 5CrMnMo, 3Cr2W8, 9CrSi, W18Cr4V, 5CrNiMo, W6Mo5Cr4V2, M2.

500~800 ℃ aluminum alloy, copper alloy, steel titanium GH130, GH33, GH37.

800~1000 ℃ titanium alloy, steel, stainless steel, nickel alloy K3, K5, K17, K19, GH99, IN100 Ж C-6NX88, MAR-M200, TRW-NASA, WA.

>1000 ℃ nickel alloy copper based alloy mold, hard alloy mold.

Contact Information

Address: No.1, Lingcheng Road, Lingcheng Industrial Park, Lingxiang Town, Dazhi City, Huangshi City, Hubei Province

Quick Navigation

Message consultation